When this process is done properly, the new cable can transmit data as quickly and efficiently as a regular fiber optic cable can.

Splice fiber optic cable professional#

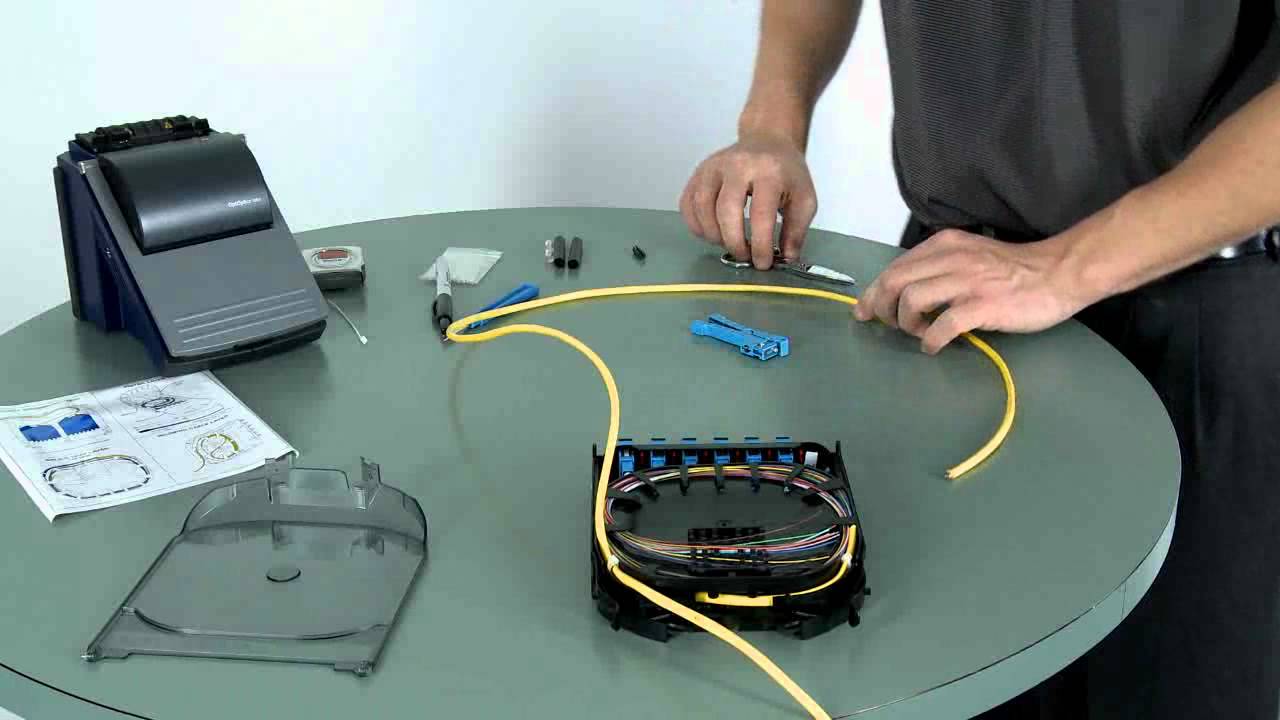

Their connection loss are usually less than 0.5dB which is much bigger than a 0.1dB fusion splice.Fiber optic splicing is a process that allows a professional to take two fiber optic cables and bring them together. They are available in permanent and reenterable types.įiber optic cable mechanical splices are available for single mode or multimode fibers. Mechanical splicing uses a small, mechanical splice, about 6cm long and 1cm in diameter that permanently joins the two optical fibers.Ī mechanical splice is a small fiber connector that precisely aligns two bare fibers and then secures them mechanically.Ī snap-type cover, an adhesive cover, or both, are used to permanently fasten the splice.įiber optic cable mechanical splices are small, quite easy to use, and are very handy for either quick repairs or permanent installations. Close and mount the splice enclosure if all splices meet the specifications.įiber optic cable mechanical splicing is an alternate splicing technique which does not require a fusion splicer. Test the splices with an OTDR or power meter from both directions. Bidirectional OTDR test (or power meter test).After all fibers have been spliced, carefully close the splice tray and place it into the splice enclosure.

Perform a OTDR test of the splice and redo the splice if necessary. Ensure that the fiber’s minimum bending radius is not compromised. Carefully place the finished splice into the splice tray and loop excess fiber around its guides. Slide the fusion splice protection sleeve on the joint and put it into the heat shrink oven, and press the heat button.

With a high precision fiber cleaver, cleave the fiber to a specified length according to your fusion splicer’s manual. After cleaning, prevent the fiber from touching anything. Carefully clean the stripped bare fiber with lint-free wipes soaked in isopropyl alcohol. Put a fusion splice protection sleeve onto the fiber being spliced. Place the fusion splice protection sleeve.For tight buffered fibers, remove 5cm of 900um tight buffer first with a buffer stripping tool, and then remove the 5cm of 250um coating. Hold the first splicing fiber and remove the 250um fiber coating to expose 5cm of 125um bare fiber cladding with fiber coating stripper tool. Strip and clean the other cable tube’s fiber that is to be spliced, and secure to the splice tray. Secure the end of the loose tube to the splice tray and lay out cleaned and separated fibers on the table. Carefully clean all fibers in the loose tube of any filling gel with cable gel remover. For a loose tube fiber cable, strip away about 2 meters of fiber tube using a buffer tube stripper and expose the individual fibers. Leave enough of the strength member to properly secure the cable in the splice enclose. Separate the fiber loose tubes and buffers by carefully cutting away any yarn or sheath. Clean off all cable gel with cable gel remover. Then carefully peel back the jacket and expose the insides. Use cable rip cord to cut through the fiber jacket. Strip back about 3 meters of fiber cable jacket to expose the fiber loose tubes or tight buffered fibers. Fiber optic cable splicing procedure (How to splice fiber optic cable) With proper training, a fiber splicing technician can routinely achieve less than 0.1dB insertion loss splicing for both single mode and multimode fiber cables. High precision fusion splicers are usually bulky and expensive. Generate a small electric arc to melt the fibers and weld them together.The fusion splicer performs optical fiber fusion splicing in two steps. Special equipment called fusion splicer is used to perform the fiber fusion splicing. Fiber mechanical splicing – Insertion loss Fiber optic cable fusion splicing – Insertion loss Both methods provide much lower insertion loss compared to fiber connectors. Two optical fiber splicing methods are available for permanent joining of two optical fibers.

0 kommentar(er)

0 kommentar(er)